CADfix Geometry Morphing

Turn CAE Displacement Results into Accurate, Usable CAD Geometry

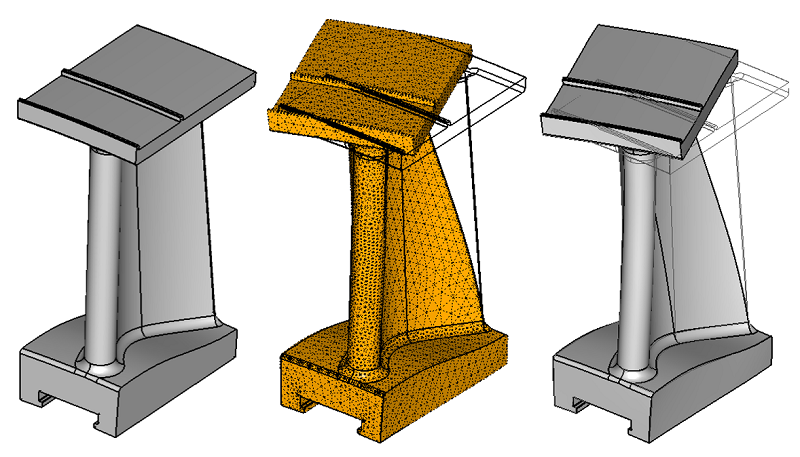

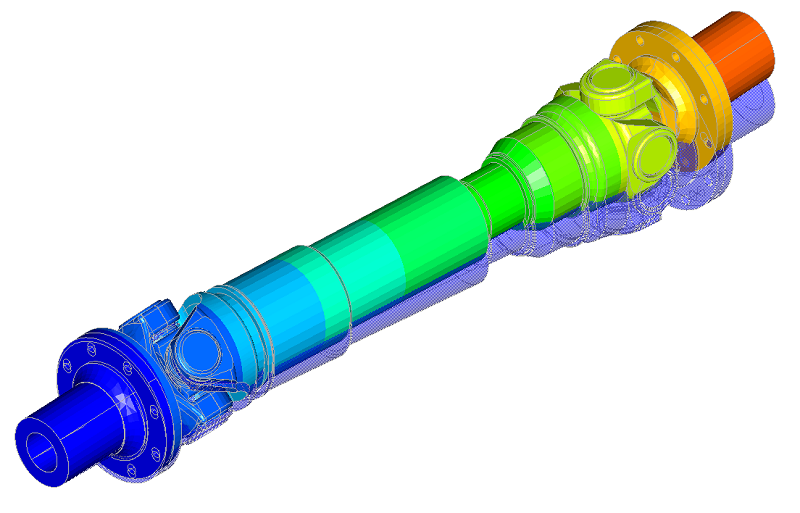

CADfix Geometry Morphing offers a robust, accurate solution for morphing or deforming original CAD model geometry to match displacement results from CAE simulations. The result is a high-quality, smooth, and well-defined geometric model suitable for re-import into CAD systems or re-meshing within CAE environments for further analysis.

Why Geometry Morphing Matters

Most CAE applications can output a displaced mesh representing the deformation of a component under real-world operating conditions. In scenarios such as:

- Multi-disciplinary analysis

- Automated shape optimization

…it’s critical to reuse the deformed geometry as input for subsequent simulations. Converting these displaced meshes into high-quality CAD geometry is often a necessary step for downstream design, verification, and manufacturing workflows.

The Problem with Traditional Reverse Engineering

A typical workaround involves reverse engineering a new CAD model from the deformed mesh using curve and surface fitting. However, this method often introduces:

- Surface irregularities

- Reduced geometric accuracy

- Models that are not viable for CAD integration

- Incompatibility with CAE re-meshing tools

The CADfix Advantage

Unlike reverse engineering approaches, CADfix morphs the original CAD geometry directly, using the existing curve and surface definitions to match the displaced mesh. This method:

- Preserves surface continuity and accuracy

- Delivers high-quality, re-usable CAD geometry

- Ensures smooth transitions in deformed regions

- Supports a wide range of input formats and displacement data sources

End-to-End Workflow Support

Whether your goal is further simulation, design adjustments, or manufacturing preparation, CADfix Geometry Morphing ensures that your morphed geometry is:

- Suitable for direct CAD usage

- Compatible with CAE meshing tools

- Ready for integration into iterative design loops

GKN Aerospace, a global leader in aerospace manufacturing, partnered with Hexagon and ITI to enhance simulation accuracy and streamline their additive manufacturing workflow. By leveraging Simufact Additive’s CAD Export feature powered by ITI’s CADfix Geometry Morphing technology, GKN was able to transform simulation-driven mesh data into accurate, parametric CAD models. This innovation enabled seamless integration with their PLM system, improved surface quality, and preserved critical design features. The result: faster design iterations, improved workflow efficiency, and significant cost savings across engineering and manufacturing operations.

Experience CADfix Geometry Morphing

Discover how CADfix Geometry Morphing can elevate your simulation-driven design process with more reliable, accurate, and reusable geometry transformations.

Contact us to request a demo or to learn how CADfix can support your specific simulation and design workflows.