CADIQ - Model Validation for the Digital Enterprise

CADIQ enables companies that are pursuing digital initiatives to automatically evaluate their 3D CAD model data across all formats, ensuring that complex engineering data is accurate and consistent throughout its usage across the product lifecycle.

Backed by ITI’s unique combination of experience in CAD validation and PLM integration, CADIQ provides a neutral third-party validation solution that establishes trust in critical model data as companies adopt significant changes across the enterprise.

Enable your business analysts to build better model-based design (MBD) processes, by leveraging CADIQ to automatically find CAD quality issues, data publishing errors and inconsistencies, and differences in models (intentional and not) from engineering change orders (ECO).

Key Capabilities

Derivative CAD Validation

CADIQ compares the source native CAD model to exported data types including QIF, STEP, JT and PDF, and automatically generates a validation report highlighting the accuracy of the published data. If differences are found, details can be reviewed to determine if the affected models can be safely used, or if corrections must be made ensuring seamless consistency and accuracy across all copies of the model.

Revision Comparison

Eliminate manual steps by automatically identifying the model changes when approving ECOs and generating ECN documentation. Unintended or accidental changes are also identified, preventing undocumented changes from slipping through approval processes into the supply chain.

Quality Checking

CAD neutral quality checking of geometry, PMI, attributes, and assembly structure provides feedback that can reduce the occurrence of publishing errors and extra Engineering Change Requests (ECR).

Comprehensive Model Analysis

CADIQ enables critical elements of CAD validation: automation, native model evaluation, and comprehensive coverage of modelling information. The extensive CADIQ model analysis encompasses geometry, product manufacturing information (PMI), attributes, and assembly structure and content. CADIQ can be integrated within PLM ensuring data security, optimal processing/analysis, and controlled reporting. CADIQ uses API interfaces for all native CAD formats to ensure no translations of data for the purpose of validation. CADIQ provides a series of reporting formats allowing model validation reports to be tailored to the right audience (both human and machine).

User-Friendly Validation Reports

Engineers benefit from user-friendly reports generated by CADIQ, including WebGL, HTML and 3D PDF, for easy, license-free access and distribution across the enterprise. These reports provide a visual representation of identified differences, facilitating clear communication of design issues. In cases where engineering data issues cannot be quickly corrected, these reports are critical for documenting and communicating these issues.

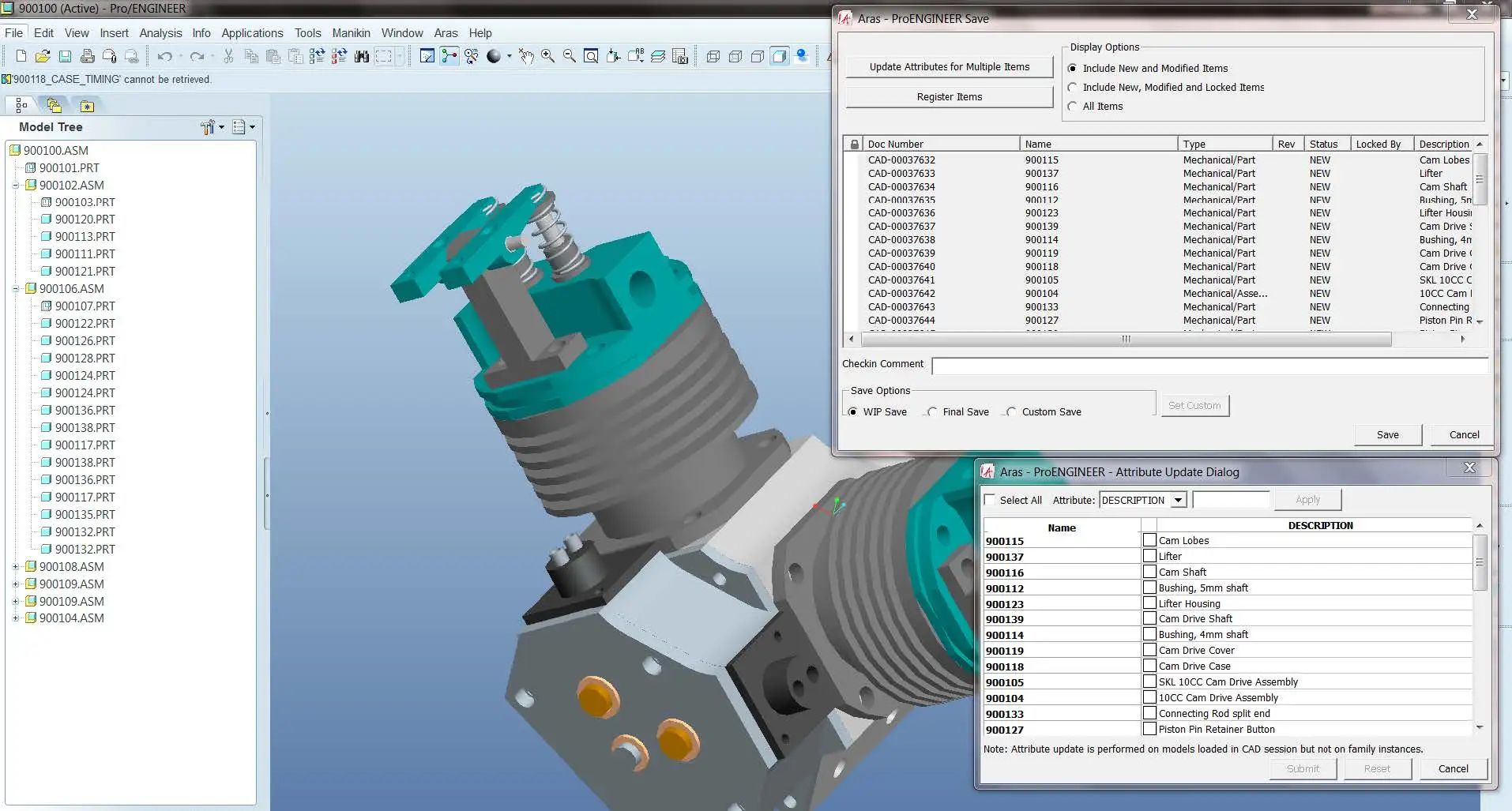

Teamcenter PLM Integration

The CADIQ integration with Teamcenter enables fully automated workflow-driven validation and increasing ease of use and efficiency.

TcCADIQ is a cutting-edge solution that efficiently integrates with Teamcenter, offering fully automated, workflow-driven validation for CAD data. This integration enhances usability and efficiency by streamlining the validation process, allowing teams to quickly assess and verify the quality of their CAD designs. With TcCADIQ, organizations can ensure compliance with industry standards while reducing manual intervention, ultimately leading to faster project turnaround times and improved productivity in the design and engineering workflow.

Windchill PLM Integration

The CADIQ integration with Windchill enables fully automated workflow-driven validation and increasing ease of use and efficiency.

Supported Native CAD Systems:

- CATIA V4

- CATIA V5

- Creo

- Inventor

- NX

- Solid Edge

- SOLIDWORKS

Supported Neutral CAD Systems:

- QIF

- STEP

- JT

- 3D PDF (PRC & U3D)

- Parasolid

- ACIS

- IGES

Data Certification

CADIQ verifies that the design model has no quality defects impeding downstream use. It also ensures derived forms of the design model (e.g., QIF, STEP, JT, etc.) are equivalent in quality and shape to the master model.

MBD Model Validation

Model-Based Design (MBD) model validation includes model-based engineering, manufacturing, and sustainability. MBD Model Validation becomes crucial for scenarios like engineering changes, legacy data migration, supplier integration, certified data delivery, long-term archival, and product lifecycle sustainment.

Long-Term Data Archival and Retrieval (LOTAR)

Engineers responsible for Long-Term Data Archival and Retrieval (LOTAR) leverage CADIQ to validate CAD models, including neutral file conversions of 3D CAD models. Support for LOTAR validation properties ensure additional data can be added to the neutral file or validated if it already exists, ensuring comprehensive validation of the retrieved model in future CAD systems decades in the future.

Boeing DPD Validation

Boeing’s D6-51991 requires suppliers to maintain the integrity of Digital Product Definition (DPD) throughout all manufacturing processes. ITI’s CADIQ provides industry-leading validation of CAD models, ensuring compliance with DPD and Model-Based Definition (MBD) standards. By identifying differences in geometry, features, and PMI, CADIQ helps aerospace suppliers deliver higher-quality models with greater confidence. With over two decades of experience supporting Boeing, ITI is the trusted partner for robust, reliable CAD validation.

Where CADIQ Can Help

Digital Thread Validation

Validate the integrity of MBE technical data packages containing derivate files such as 3D PDF and QIF created by content generators Anark and Capvida.

CAD Model Quality

Improve overall CAD model quality and ensure robust CAD models throughout the product lifecycle.

MBD/MBE

Quickly check the quality of 3D CAD models and PMI entities in master model parts and assemblies.

Data Delivery Certification

Verify design model quality and equivalence of derived forms (IGES, STEP, CAD translation, etc.) to the master model.

Boeing DPD

Help suppliers meet D6-51991 standard for maintaining DPD integrity.

LOTAR

Certify CAD models to support long-term auditable archiving and retrieval processes.

Contact Us Today

Explore how CADIQ can revolutionize your CAD validation and revision comparison processes, ensuring data integrity and optimizing downstream re-use.